|

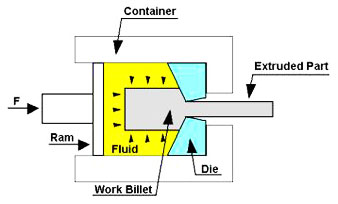

Hydrostatic Extrusion

Hydrostatic extrusion is a process in which the billet is completely circumscribed by a pressurized liquid in all the cases, with the exception being the case where billet is in the contact with die. This process can be carried out in many ways including warm, cold or hot but due to the stability of the used fluid, the temperature is limited. Hydrostatic extrusion has to be carried out in a completely sealed cylinder for containing the hydrostatic medium. The fluid may be pressurized in following two ways:

- Constant-Rate Extrusion: A ram or plunger is used for pressurizing the fluid in the container

- Constant-Pressure Extrusion: A pump with a pressure intensifier is used for pressurizing the fluid, which is then pumped into the container

Advantages of Hydrostatic Extrusion Advantages of Hydrostatic Extrusion

- No friction amidst the container and billet. This minimizes the force requirements, allowing higher reduction ratios, faster speeds, & lower billet temperatures.

- Friction of the die can be largely reduced by a film of pressurized lubricant amidst the die surface and deforming metal.

- On applying high pressures, the ductility of material increases.

- Even flow of material.

- Large billets & large cross-sections are extruded.

- Uniform hydrostatic pressure inside the container eliminates the requirement of billets being straightened and extrusion of coiled wire.

- No billet residue is left on the walls of container.

Disadvantages of Hydrostatic Extrusion

The billets have to be prepared by tapering one end so that it matches the die entry angle. This is essential for forming a seal at the starting of the cycle. Generally, the complete billet is required to be machined for the removal of surface defects.

It can be difficult to contain the fluid, under the effects of high pressures (up to 2 GPa, or 290 ksi).

Limitations of Hydrostatic Extrusion

There are a number of limitations in the hydrostatic extrusion, especially when a large volume of fluid is used in comparison with the billet volume, which is to be extruded. These limitations are as follows:

- Increased handling for the injection and removal of the fluid for every extrusion cycle

- Decreased control of speed of the billet & stopping because of potential stick-slip and enormous stored energy in the compressed fluid

- Decreased process efficiency in terms of billet-to-container volume ratio

- Enhanced complications, when extrusion is done at elevated temperatures

Solutions To These Limitations

The problems related to the billet speed as well as stopping control can be minimized with the use of viscous dampers and also with the improvement in lubrication at the billet / die interface. There is another approach to minimize all the above mentioned problems, which is to maintain the amount of pressurizing fluid to an absolute minimum, as in the case of Hydrafilm process.

|

|

|

|